When staining is part of the finishing regimen for a woodworking project, most of us pull out the same options for applying it: a brush of one kind or another, or maybe an old T-shirt or sock from the rag bag. But, while these alternatives are commonplace and cheap, they might not actually be the best choices for the task.

A couple of years ago, Jarred Brown — a longtime woodworker and DIYer — was about to finish a custom cabinet project with his dad. It was time for stain, but the choice of how to apply it suddenly seemed ironic as he reached for the family rag bag.

“I told my dad, between the two of us, we had more than 40 hours into the design and 80 hours into building the project, and we were about to stain it with my old T-shirt,” Brown recalls. “There had to be something better than that, but when he asked me what I might suggest, I had no idea.”

In search of a better solution, the two went to Home Depot and their local Rockler store in Denver, Colorado. They bought samples of nearly every available stain applicator option — stain pads, various quality cloth rags, microfiber rags, foam brushes and both expensive and cheap bristle brushes.

After giving them all a try, “each of them had tradeoffs and shortcomings,” Brown says.

They found that rags, while ubiquitous and often free, aren’t great for applying stain into corners without streaking the material. They snag and often leave lint behind, particularly on roughsawn and reclaimed wood. And, if wadded up with oil-based stain, rags can pose a fire hazard.

Foam brushes are another option. “They’re inexpensive, disposable, present less fire hazard, provide even pressure and have a chisel end for corners,” Brown says. But they, too, often snag and rip. “I have yet to find one where the foam doesn’t almost immediately fall off the handle during use. So promising, yet so frustrating.”

Traditional bristle brushes will apply stain reasonably well, but Brown believes their reservoirs soak up too much product, which is problematic when excess liquid releases onto the wood surface. “All but the most expensive brushes tend to leave bristles and/or brush marks behind,” Brown adds, “and personally, I just hate cleaning out brushes — especially with oil-based products.”

Finally, Brown and his dad tried stain pads, which are typically foam covered with terrycloth. Terrycloth snags on wood fibers and produces lint, and the size of the pads is too large to fit into small cans of stain. “Since they’re just terrycloth sewed around foam, you can’t cut them to a desired size, either,” he adds.

What seemed to work best for their cabinet project was to apply the stain with a foam brush, followed by smoothing it with an old T-shirt. The process was time-consuming and frustrating, Brown admits, but it provided the best overall finish. Then the “Eureka!” moment hit.

“It occurred to me to glue that old T-shirt to the foam brush,” Brown says.

While the T-shirt worked OK, they also tried terrycloth, microfiber and various other fabrics glued to the foam to see how they would compare.

“You should have seen my shop. I had cans of spray glue, foam and different types of cloth everywhere! I had glue on my hands for weeks. I couldn’t walk through my shop, or anywhere for that matter, without my shoes sticking to the floor,” Brown recalls.

Even so, the effort and the mess proved worthwhile. When Brown had a “prototype” that worked better than others, he shared it with the staff at his local Rockler store. “I figured, I liked it, but these guys actually know what they are doing,” Brown says. “Their encouragement and excitement for the product is a big part of what kept me going.”

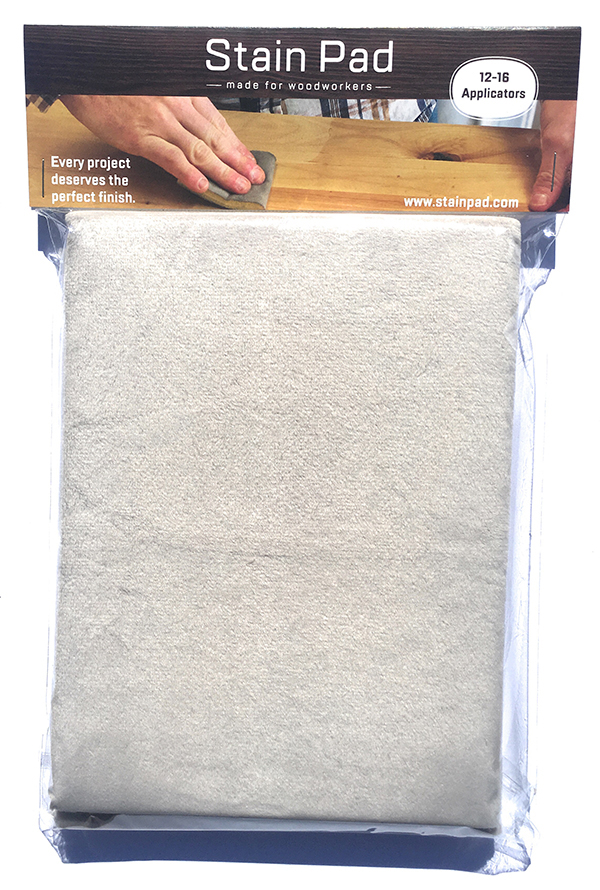

The culmination of trial-and-error, bolstered by positive feedback and some business experience, led Brown to bring his Stain Pad product design to market. It launched in November of last year. It’s a 6- x 8-in. composite pad, made up of a microfiber outer layer fused to an inner layer of medium-porosity, open-celled foam. There’s also an impermeable membrane in the middle to block stain from going all the way through the pad, so one side can be used for an applicator and the other side for wiping the stained surface smooth.

Brown points out a number of design advantages that Stain Pad has over the usual cast of characters we use for applicators. One of them is size: Stain Pad can easily be cut with a scissors to fit the size of the stain can you’re using, as well as to customize its shape to fit into the corners of projects.

Its outer microfiber layer resists solvents and won’t unravel or leave lint. “Because of its loop-less, brush-like fabric, Stain Pad really resists snagging, even on the roughest woods,” Brown adds.

Stain Pad’s inner foam layer also loads a more appropriate amount of liquid for staining applications than a rag or a brush. Brown says he opted for “middle-of-the-road” in terms of the porosity and permeability of the foam — two factors that influence how much material is absorbed and how quickly it is released from the pad. “It works well on thin stains as well as gel stains,” Brown says.

The thin, open-celled foam also improves safety. Brown explains that stain will dry on the pad before there’s a possibility for oil-based product to heat up and spontaneously combust, but he recommends that it’s still a good idea to let Stain Pads dry flat or alone in a metal can before disposing them in the trash.

Stain Pads are designed to be used with either oil- or water-based stains, and Brown adds that they also excel at applying polyurethane.

“I’ve never laid down a more clear or perfect poly finish,” he says. “The key for me, when using Stain Pads with poly, is three steps: First, apply the poly with some pressure. Then smooth it with long, light and even strokes. And finally, walk away — this is the most important step.”

Brown says he’s also had good success using Stain Pads with Waterlox finish and General Finishes Wipe-on Poly. He can’t testify from personal experience how they work for applying shellac or lacquer, but he’s heard from others that Stain Pads are suitable for these finishes, too.

Developing Stain Pads has presented some challenges, Brown admits. Getting UPC and HTS codes, learning the Amazon platform, setting up his website and figuring out packaging and shipping solutions have all come with their share of learning curves. But Brown’s experience as a CPA, auditor and former owner of a consulting business has made the financial hurdles and questions easier to navigate. It has helped to have a patent litigator for a neighbor and cousins who are graphic designers. He also feels indebted to the staff at Rockler who have been willing to offer feedback along the way.

“Some might say I have found a solution to a problem that wasn’t there, but for me, the ‘Why?’ question presented itself. I faced a problem and didn’t like the solutions, so I created an alternative that I think is better,” Brown says. “Problem solving in itself is gratifying and empowering. And now, I really like using the product (I’ve made). I find that I get much better results, and I just like using it.”

Learn more about Stain Pads by clicking here. To order them from Rockler, click here.